PRODUCTS

Contact Us

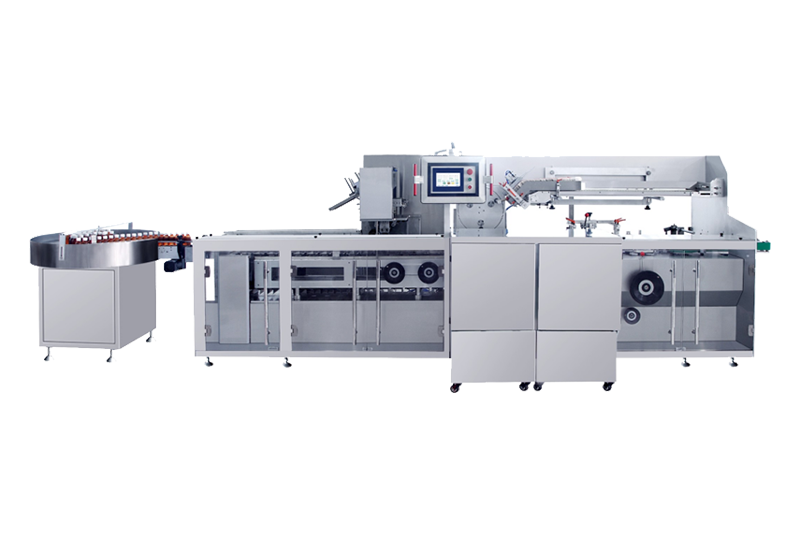

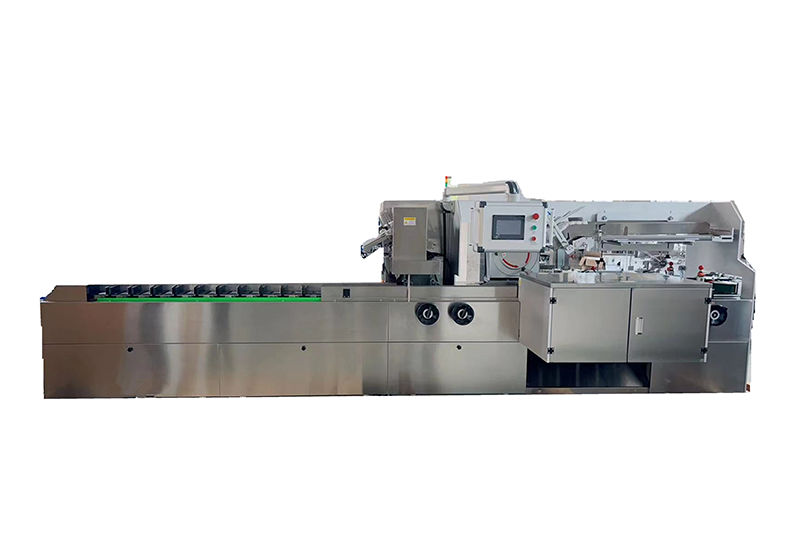

ZHJ-120F Automatic Cartoning Machine

Category:

Automatic cartoning machine

Product Description

This machine is suitable for packing blister, tubes, ampoules,food,cosmetics and other related objects into boxes intermittently. The highest speed can up to 50 boxes/min. It has advantages of high packing efficiency and good quality, and is hi-tech product with structure of mechanical-electrical integration. It adopts frequency inverter to adjust speed, human machine interface to operate, PLC to control, and photoelectric to supervise and control each station. So that once something unexpected happens during its running, it will stop and display the reasons automatically, which can solve the troubles in time.

Note: this machine can also equip hot melt glue device to do hot melt glue sealing for box.

Usage and Apply Scope

- This machine can feeding, fold leaflet, open box, insert blister into box, batch number printing, close box and waste rejecting automatically.

- This machine is controlled by PLC. The photo-electricity will control each movement. While there is anything abnormal during running, the machine can stop automatically and display the reason on touch screen, so that it will be easy for you to clear the malfunction.

- There are main driving motor and clutch detent in machine base, and overload protector in each transmission system on machine plate. Thus when overload, the main driving motor and each transmission parts will separate to ensure safety of whole machine.

- With wide packing range and convenient adjustment, fast switching among various specifications and sizes can be realized.

- This machine is with reject device. The leaflet, blister, carton will go through sensor inspecting, and output after letter embossing and carton closed. Thus if there is no leaflet or blister, the carton will be rejected.

- This machine can be separately used, and also can be connected to blister packing machine or any other equipment to be production line.

|

Model |

ZHJ-120F |

|

Production capacity |

30-60box/min |

|

Box Size |

Max: 320×210×80mm (L*W*H) |

|

Min: 70×30×15mm (L*W*H) |

|

|

Specification of box |

250-350g/㎡ |

|

Leaflet size (if need) |

Max: 220×180mm (L*W) |

|

Min: 100×100mm (L*W) |

|

|

Specification of leaflet |

60-70g/㎡ |

|

Volume of air consumption |

20m³/h (pressure 0.5-0.7Mpa) |

|

Main Motor Power |

1.5KW |

|

Power supply |

380V 50HZ |

|

Overall Size |

3700×1320×1700mm (L*W*H) |

|

Weight |

About 1800Kg |

Transmission structure

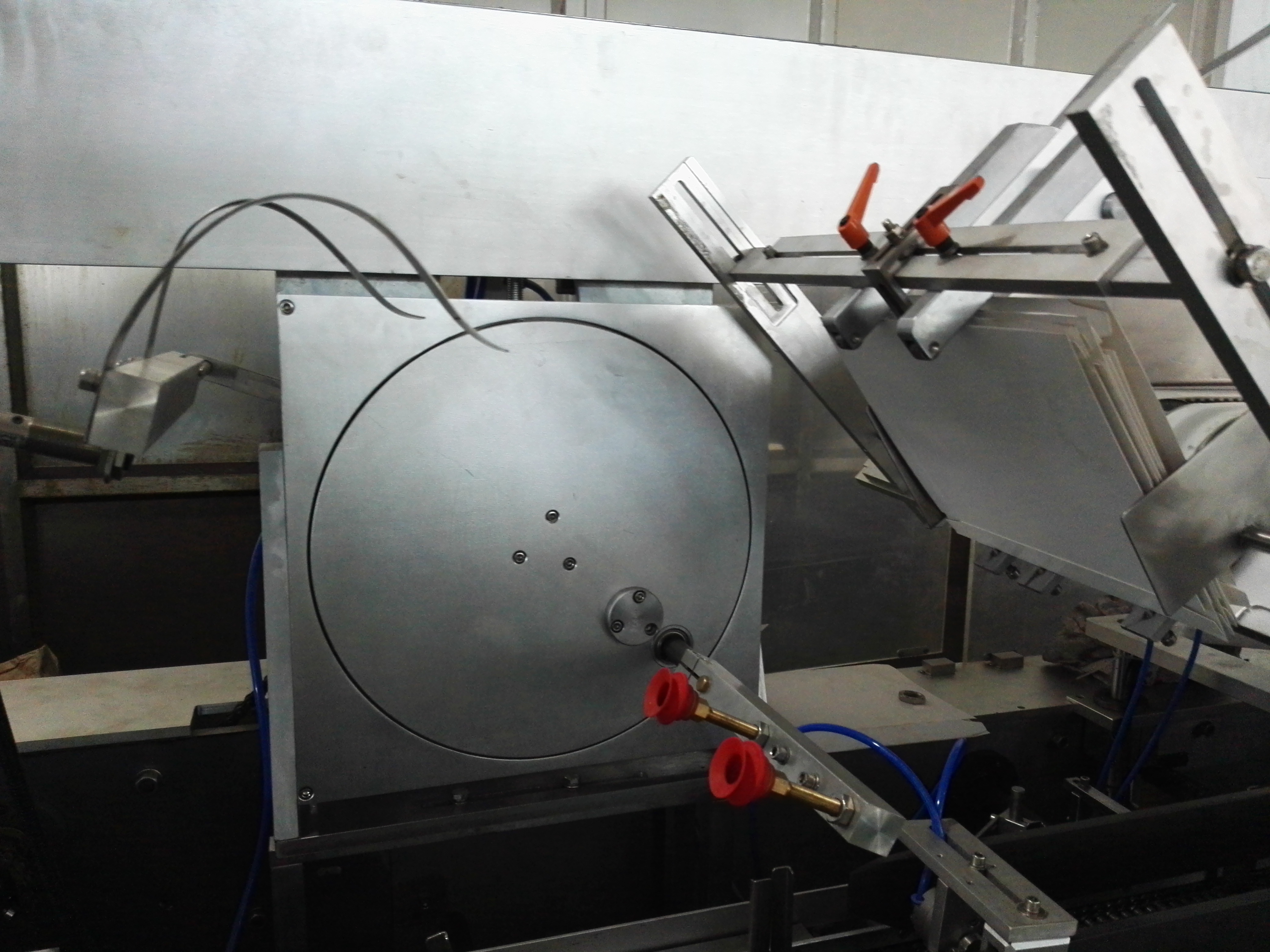

Open box structure

Box storage

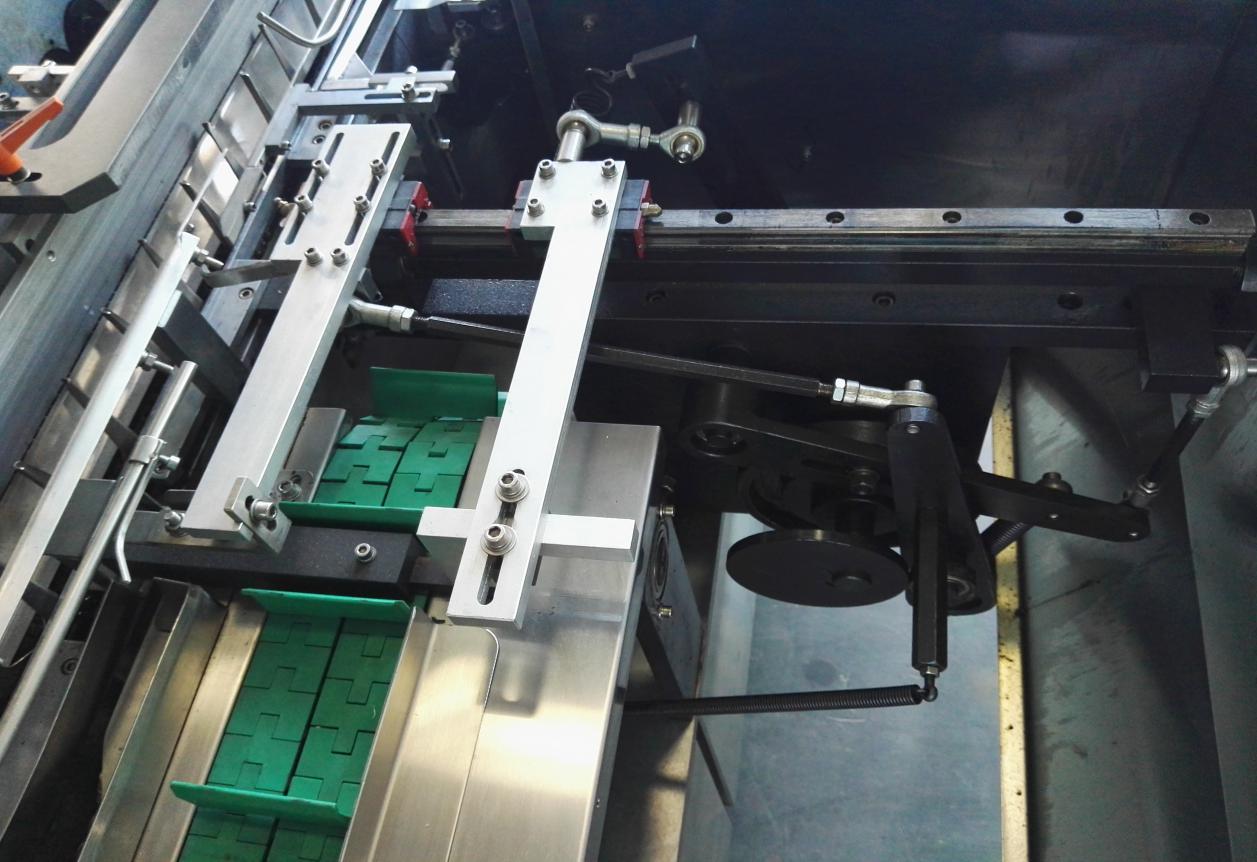

Putter structure

Box transport part

PACKING LIST

|

No. |

Name |

Q’TY |

Remarks |

|

1. |

ZHJ120F Automatic Cartoning machine |

1 |

|

|

2 |

“0-9”embossing letters |

10 each |

|

|

3. |

“一 十” type Screwdriver |

1 each |

|

|

4 |

Paper Clip |

5 |

|

|

5 |

4,5,6,8,10mm Allen wrench |

1 each |

|

|

6 |

14—17 Wrench |

1 |

|

|

7 |

8—10 Wrench |

1 |

|

|

8 |

Vacuum suck tray |

4 |

|

|

9 |

Flat adhesive tape |

6 |

|

|

10 |

Synchronize dentiform belt 244L075 |

1 |

|

|

11 |

Oil pistol |

1 |

|

|

12 |

Plastic chain |

5 each |

|

|

13 |

Hot melt glue machine(nordson) |

1 |

|

|

Document |

|||

|

1 |

Manual |

1 |

|

|

2 |

Quality Certificate |

1 |

|

|

3 |

Company CD |

1 |

|

|

4 |

PLC/ HMI/ Transducer CD |

1 |

|

Configuration list

|

Name |

Qty.(set) |

Brand |

|

TOUCH SCREEN |

1 |

Mitsubishi |

|

PLC |

1 |

Mitsubishi |

|

Transducer |

1 |

Mitsubishi |

|

AC Contactor |

1 |

Schneider |

|

INVERTER |

1 |

Mitsubishi |

|

Small Relay |

5 |

Omron |

|

Intermediate relay |

2 |

Schneider |

|

Solid Relay |

3 |

Omron |

|

Motor |

1 |

GPG |

|

SERVO MOTOR |

1 |

DELTA(TAIWAN) |

|

Photoelectric Switch |

3 |

SICK |

|

Proximity Switch |

2 |

Turck |

|

Air switch |

I for each |

Schneider |

|

Switch Group |

1 |

Chang Jiang |

|

Power Switch |

1 |

Omron |

|

Solenoid Valve |

5 |

AirTAC |

|

Circuit Breaker |

1set |

Schneider |

|

Vacuum Generator |

2 |

Vtec |

|

Vacuum Chuck |

3 |

Vtec |

|

Cylinder |

1 |

AirTAC |

|

Button Group |

I for each |

Schneider |

|

Communication Module |

1 |

Mitsubishi |

|

Stainless Steel Material |

|

|

Related Products

Welcome your message consultation