PRODUCTS

Contact Us

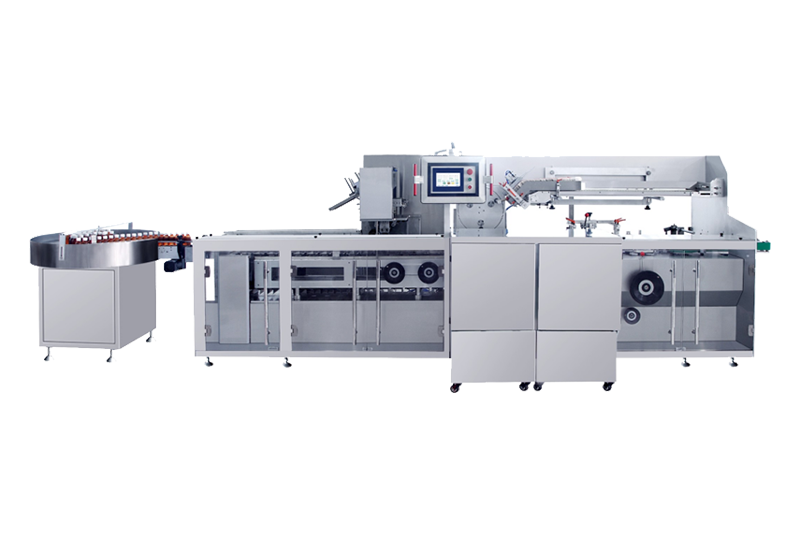

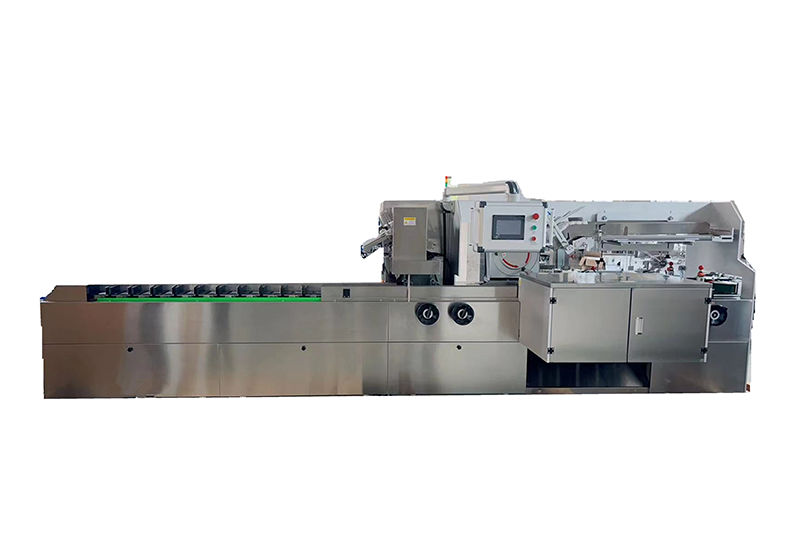

JK-550B Automatic Carton Packing Production Line

Category:

Automatic case open- case filling -case sealing machine

Product Description

First Part : Automatic Case Opening Machine

1. General Description

It can automatic case opening , bottom folding flap and bend flap, and bottom tape sticking, case transport out and other functions, It is economical and efficient.

2. Technical Data

|

Machine dimension |

L2000mm×W1900mm×H1450mm |

|

|

Applicable case range |

L: MAX600 - min200 |

|

|

W: MAX500 - min150 |

||

|

H: MAX350 - min100 |

||

|

Case capacity |

Max 720 pcs/h |

|

|

Case stack volume |

100 pcs/h(Corrugated case) |

|

|

Case material |

General specification corrugated paper |

|

|

Use tape |

OPP; Kraft paper 38 mm or 50 mm width |

|

|

Case size exchange |

Handle adjustment for about 1 minute |

|

|

Power supply |

single phase 220V |

|

|

Air source |

0.5MPa(5Kg/cm2) |

|

|

Air consumption |

300L/ min |

|

|

machine weight |

About 600Kg |

|

3. Functions and Options

The whole operation process must be completed in a stable state, with adequate reliable positioning and protection measures, so can not cause damage to case. Production capacity: 1-3 case/min.

1. Open case smoothly and beautifully. The success rate and qualified rate of opening case is more than 99.9%.

2. It better for single machine independent debugging and production control screen interface, and it has the digits showing of output counting, machine running speed and equipment failure, Chinese display and prompt. It has safety protection functions such as fault alarm, fault stop machine and emergency stop machine.

3. The size of case can be adjusted conveniently and accurately by handwheel.

4. Structure about every assembly unit

1.Adopt 4 sets of Japanese SMC suckers, the positioning can be adjusted accurately, so that the carton can be opened smoothly, the qualified rate of opening can be greatly improved, and the folding and scrapping of case can be avoided.

2. The double cylinders combined with the swing arm folding cover solved the problems of single cylinder balance and inadequate force causing the folding cover to be inadequate.

5.Main Component List

|

Name |

Model and Specification |

Place of Origin or Brand |

|

Power Switch |

EEC60947 |

HELLY |

|

Emergency Stop Button |

ZB2-BE102C |

France Schneider |

|

CPU |

224CNS |

Germany Siemens |

|

AC contactor |

CJX20910 |

china zhengtai |

|

Filter protector |

NR2-25 |

china zhengtai |

|

Switch Power |

ABL2REm24020H |

France Schneider |

|

Relay |

Rh2B-u |

Japan IDEC |

|

Breaker |

D247-60 C25 |

china zhengtai |

|

Breaker |

D247-60 C10 |

china zhengtai |

|

Motor |

CONT |

china taibang |

|

Touch screen |

TPC7062KS |

beijing kunlun |

|

Cylinder |

PC 32B80-C |

SHAKO |

|

Electromagnetic Valve |

4V210-08 |

Taiwan AirTAC |

|

Cylinder |

PC 40B30-C-CB |

SHAKO |

|

Cylinder |

PC 32B200-C |

SHAKO |

|

Cylinder |

PC 50B250-CA |

SHAKO |

|

Vacuum Valve |

2HBD |

Japan SMC |

|

Magnetic switch |

LYDTEK |

jiazhun |

|

Photoelectric Switch |

WT100-N1432 |

SLCK |

Second : Automatic Case Filling Machine

1. General Description

2.Technical Parameters:

|

Machine Dimension |

L2100×W1300×H1900mm(Can Customize) |

|

Filling Capacity |

80~500 Carton/Min |

|

Filling Product |

Carton And So On |

|

Power Supply |

AC220V |

|

Power |

0.4Kw |

|

Air Pressure |

0.5~0.6Mpa(5~6Kg/Cm2) |

|

Air Consumption |

350L/ Min |

|

Machine Weight |

About 7 |

3.Technical requirements:

1.It can be adjusted conveniently and accurately when the size of palletizing and carton changes.

2.It has single-machine independent debugging and production control, output counting by control screen interface, machine speed adjustment and display equipment failure and other figures, Chinese

3.It has safety protection functions such as inspection and monitoring of carton quality and storage, fault alarm, fault shutdown and emergency shutdown.

4.The qualified rate of filling case is 100%; (When filling fails due to special reasons, the equipment alarms and stops, and the filled goods (cartons) are handled manually).

5.when filling is smooth and does not damage the appearance of the case. The appearance of the finished case is intact and neat, and the qualified rate of the appearance is 99.5%.

4. Structure about every assembly unit

1.Pressure pulley guide to ensure accurate material delivery in place

2. High precision guideway, with imported synchronous belt grabbing material mechanism, to ensure the stability and durability of equipment

3. 304 stainless steel power roller, smooth and fast conveying, to achieve zero wear and tear of case

5.Main Component List

|

Name |

Model And Specification |

Place Of Origin Or Brand |

|

Touch Screen |

TPC7062ks |

France Schneider |

|

Indicator Light |

AD105-220/531 |

France Schneider |

|

Power Switch |

LA39 |

France Schneider |

|

Emergency Stop Button |

Z2B2-BE101C |

France Schneider |

|

Motor |

5RK40GU-CF200W |

Zhejiang WAILI |

|

Magnetic Switch |

CSL-U |

NBSKK |

|

Photoelectric Switch |

E3F-DS30C4 |

Lulong |

|

Proximity Switch |

QL-05N |

Japan Omron |

|

Switch Power |

ABL2REm24020H |

France Schneider |

|

CPU |

224CN |

France Schneider |

|

Breaker |

D247-60 C25 |

France Schneider |

|

Breaker |

D247-60 C10 |

France Schneider |

|

Breaker |

PH2B-U |

Japan IDEC |

|

Electromagnetic Valve |

TG2521-08 |

Taiwan Airtac |

|

Motor |

5RK90RG-CF 90W |

Zhejiang WAILI |

|

Motor |

5RK90RG-CF 120W |

Zhejiang WAILI |

|

Servo Motor |

MHMD042G1U |

France Schneider |

|

AC Contactor |

E2510 |

France Schneider |

|

Cylinder |

SU32X50 |

Taiwan Airtac |

|

Cylinder |

SU32X180 |

Taiwan Airtac |

|

Cylinder |

SU32X220 |

Taiwan Airtac |

|

Cylinder |

SU50X100 |

Taiwan Airtac |

|

Cylinder |

SU80X300 |

Taiwan Airtac |

|

Cylinder |

MAL20X55 |

Taiwan Airtac |

|

Cylinder |

TN16X40 |

Taiwan Airtac |

Third Part : Automatic Case Sealing Machine

1. General Description

It can automatically bend the upper inner folding flap of the case and stick the sealing case with tape.

2.Technical Parameters

|

Machine Dimension |

L1830mm*W835mm*H1640mm |

|

|

Applicable Case Range |

L:MAX600 Mm - MIN200 Mm |

|

|

W:MAX500 Mm - MIN180 Mm |

||

|

H: MAX350mm - MIN100 Mm |

||

|

Sealing Case Capacity |

Maximum 720 Cases/ Hour For Common Specifications |

|

|

Power Supply |

Single Phase220v 50Hz |

|

|

Air Supply |

50KG/CM2;50L/Min |

|

|

Machine Weight |

About 250KG;Foot Wheel 4pcs |

|

3.Technical Requirements:

1. The whole operation process must be completed in a stable state, with adequate and reliable positioning and protection measures, so as not to cause damage to cartons. Production capacity (> 5 cartons/min).

2. Case sealing is smooth and beautiful. Successful sealing and qualified rate is 100%

3. It has single-machine independent debugging and production control, output counting by control screen interface, machine speed adjustment and display equipment failure and other figures, Chinese (optional) .It also has safety protection functions such as fault alarm, fault shutdown and emergency shutdown. (optional)

4. The size of case can be adjusted conveniently and accurately by handwheel.

4.Main Component List

|

Name |

Model And Specification |

Place Of Origin Or Brand |

|

Emergency Stop Button |

YW-E01 |

France Schneider |

|

Button |

YW-E10 |

France Schneider |

|

Indicator Light |

APT |

France Schneider |

|

Switch |

IEC60947 |

France Schneider |

|

AC Contactor |

0910 |

ZHENGTAI |

|

Relay |

RH2B-U |

JAPAN IDEC |

|

Motor |

CONT |

Taibang |

|

Valve |

IL40C100-CA |

SHAKO |

|

Travel Switch |

60947<5-1 |

France Schneider |

|

Conveyor |

|

Shanghai |

|

Electromagnetic Valve |

SY4V210-08 |

Taiwan Airtac |

roller conveyor

It is used for connecting and conveying between unpacking machine, packing machine, sealing machine, strapping machine and palletizing.

Technical requirements: (reserved cardboard feeding machine, instruction manual feeding machine, supervision code scanning, corner labeling machine, inkjet printer station)

1. The conveying capacity meets the requirements of packing efficiency, and the speed is adjustable.

2. It can be adjusted conveniently and accurately when the packaging specification and size change again.

3. The entire conveying process must be stable, smooth, and reliable in place, with sufficient and reliable positioning, guidance and protection measures, and must not cause damage or damage to the conveyed products.

Conveyor belt structure:

Mechanical stacker

MD-1200 palletizer has the characteristics of high degree of automation, reliable operation, and is suitable for large-scale and multi-variety production. It is an ideal equipment for eliminating backward manual packaging. It can improve the degree of automation, reduce the labor intensity of workers, prevent pollution, reduce damage and improve transportation capacity.

Technical Features:

1. Simple structure and few parts. Therefore, the failure rate of parts is low, the performance is reliable, the maintenance and repair are simple, and the required parts in stock are few.

2. Small footprint. It is beneficial to the layout of the production line in the customer's factory building, and can reserve a large warehouse area. The palletizing robot can be set up in a narrow space and can be used effectively.

3. Strong applicability. When the size, volume, shape of the customer's product and the external dimensions of the tray change, it is only necessary to make a slight modification on the touch screen, which will not affect the normal production of the customer. The change of the mechanical palletizer is quite troublesome or even impossible.

4. Low energy consumption. Usually the power of mechanical palletizer is about 10-25KW, while the power of MD-1200 palletizer is about 5KW. Greatly reduce the customer's operating costs.

5. All controls can be operated on the screen of the control cabinet, and the operation is very simple.

6. Only need to locate the starting point and placement point, the teaching method is simple and easy to understand main technical parameters:

|

model

|

MD-1200

|

|

power supply

|

Three phase 380V

|

|

power

|

4kW

|

|

electric current

|

10A

|

|

barometric pressure

|

0.6-0.8MPa

|

|

Air consumption

|

100L/min

|

|

size

|

3750*1650*2300mm

|

|

weight

|

650kg

|

Main configuration list:

|

No. |

Name |

specification |

Brand |

|

1 |

breaker |

OSMC32N4C40 |

Schneider |

|

2 |

breaker |

OSMC32N3C20 |

Schneider |

|

3 |

breaker |

0SMC32N2C10 |

Schneider |

|

4 |

breaker |

OSMC32N1C10 |

Schneider |

|

5 |

TM241CE40T |

TM241CE40T |

|

|

6 |

module |

TM3DI16 |

Schneider |

|

7 |

module |

TM3DQ16T |

Schneider |

|

8 |

PLC output amplifier board (optocoupler) |

BLX-A model |

GC |

|

9 |

Intermediate relay |

RXM2LB2BD |

Schneider |

|

10 |

relay base |

RXZE1M2C |

Schneider |

|

11 |

AC contactor |

LC1N401OM5N |

Schneider |

|

12 |

contactor |

LC1N1210M5N |

Schneider |

|

13 |

thermal overload relay |

LRN10N |

Schneider |

|

14 |

16 servo drives |

LXM16DU04M2X |

Schneider |

|

15 |

16 servo drives |

LXM16DU07M2X |

Schneider |

|

16 |

16 servo motor |

BCH16HD04330A5C |

Schneider |

|

17 |

Missing neutral line protection |

DPA51CM44 |

|

|

18 |

switching power supply |

ABL2REM24065K |

Schneider |

|

19 |

button base |

ZB2BZ101C |

Schneider |

|

20 |

green button |

ZB2BA3C |

Schneider |

|

21 |

yellow button |

ZB2BA5C |

Schneider |

|

22 |

key knob |

Key knob |

Schneider |

|

23 |

red button |

ZB2BA4C |

Schneider |

|

24 |

button base |

ZB2BZ102C |

Schneider |

|

25 |

emergency button |

ZB2BS54C |

Schneider |

|

26 |

servo motor |

BCH16HD04330A5CZ |

Schneider |

|

27 |

power line |

W3M5A11R07 |

GC |

|

28 |

coding line |

WW3M8A11R07 |

GC |

|

29 |

power line |

WV3M5A12R07 |

GC |

|

30 |

CN1 control line |

Imodel CN1-1.5M |

GC |

|

31 |

touch screen |

HMIGXU3512 |

Schneider |

|

32 |

gateway wifi |

wifi |

easy |

|

33 |

motor |

6IK200GU-CF1:7.5(with speed regulation) |

Taibang |

|

34 |

cylinder |

HRQ-50-S-buffered |

AirTAC |

|

35 |

The electromagnetic valve |

4V210-08 |

AirTAC |

Pre

Related Products

Welcome your message consultation